Carlsbad, Calif., August 26th 2021.

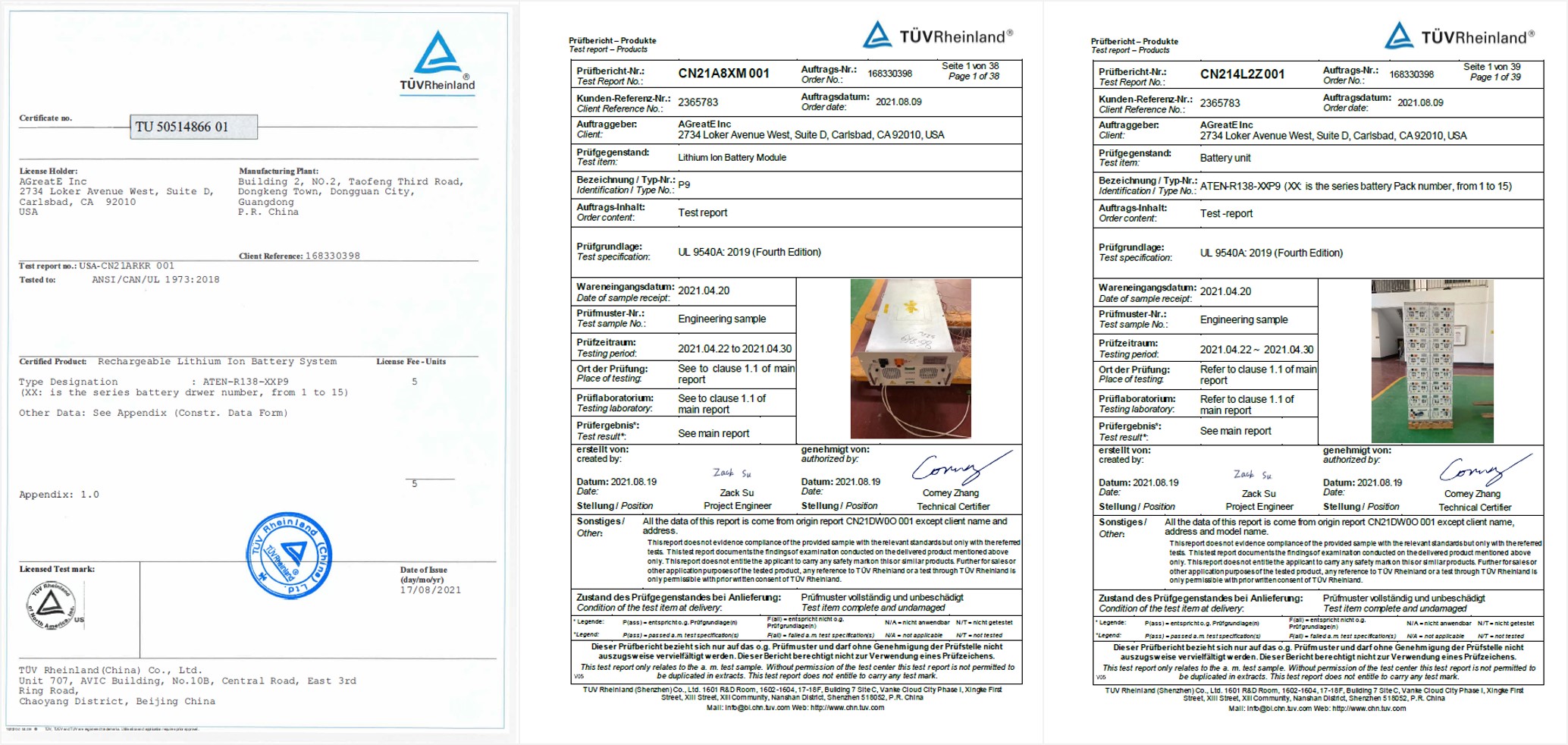

After months of stringent testing and evaluation, AGreatE’s LFP battery energy storage system – ATEN ® – has passed UL 9540A (standard test method for evaluating thermal runaway and fire propagation in battery energy storage systems) and received UL 1973:2018 (a standard for batteries for use in light electric rail LER applications and stationary applications) certifications from UL (Underwriters Laboratories).

ATEN battery energy storage solutions are typically used in commercial on & off grid applications and offered in both AC and DC coupled configurations. Larger systems can be configured using the ATEN 138 Rack into multi MW energy storage systems. The UL 1973 testing allows AGreatE to configure its battery systems with PCS suppliers that have UL 1741 inverter certification and combine them to offer the UL 9540 as a completely certified battery energy storage solution. The UL 9540A testing is also a key aspect for BESS safety as it provides quantitative data to characterize potential ESS fire events.

“This independent verification of both UL 9540A and UL1973 by UL should instill confidence in our clients and partners about the safety, quality, and reliability of our battery energy storage systems moving forward.” said Tom Xu, CEO of AGreatE Inc.

The future of renewable and distributed energy is reliant on ES and the focus on fire risks, standards and planning are key. Manufacturers (such as AGreatE inc,) operators, and first responders need to continue working together to enhance protocols and training to allow for safer BESS deployment.

What is UL 9540A?

UL 9540A, “Test Method for Evaluating Thermal Runaway Fire Propagation in Battery Energy Storage Systems” was developed by UL to address a requirement in the International Code Council’s International Fire Code and a similar anticipated requirement in the installation standard, NFPA 855, Installation of Energy Storage Systems for large scale fire testing. Fire Code and building codes have placed strict limitations on the size and quantity of energy storage systems as well as separation distances between systems and between systems and structures that can be installed in mixed use occupancies. These limitations on size are based upon energy limits and are technology dependent. The large scale fire testing can be used to assess the risk and probability of fire propagation in order to reduce separation distances, increase size (energy) of systems to be installed, and show effectiveness of fire suppression systems.

The results from the UL 9540A test method is intended to address the following key areas of concern identified by building code and fire code officials:

- The appropriateness of the battery energy storage system (BESS) installation instructions with regard to separation distances and location of cabling to and from the system

- Installation ventilation requirements

- Effectiveness of fire protection and deflagration mitigation strategies, and

- Information necessary for fire service strategy and tactics in the event of a fire involving the BESS.

The test method has several different levels of testing. The first level, is the cell level testing, whose purpose is to determine a method for consistently creating a thermal runaway condition in a cell and for collecting temperature to venting, collecting and identify gases vented from the cell upon completion of the cell level testing, the testing moves on to the module level testing. This level is also an information gathering step. One or more cells in a module are driven into thermal runaway, and the effects of the fire to lead to propagation in the module is evaluated. The same procedure for failing cells at the module level is then replicated at the unit level, with one module that is located within the energy storage system, where there is the potential for worse case conditions. For the unit level tests on initiating battery energy storage system BESS unit representative of what is to be installed in the field, is subjected to the cell failing in one of its modules, while the other modules. A final installation level test can be done in cases where fire mitigation and suppression devices are installed in addition to the BESS unit to mitigate/suppress the fire & deflagration propagation hazard.

What is UL 1973 2018?

UL 1973 is a Standard for Batteries for Use in Light Electric Rail (LER) Applications and Stationary Applications. UL 1973 is well known and a globally accepted safety standard for stationary batteries and has been recently revised to the 2nd edition in February 2018. A UL 1973 battery system is ultimately a component of a UL 9540 energy storage system, and not a replacement of evaluating a full ESS. UL 1973 is technology agnostic but does have a number of specific criteria for different technologies of batteries such as lithium ion, sodium beta batteries and flow batteries.

UL 1973 is structured in a similar manner as UL 9540 as it contains both construction criteria, and testing as well as labeling, marking, and user instruction requirements. As with UL 9540, UL 1973 has requirements for a safety analysis of the battery system, to ensure that the BMS and other protections provided with the battery maintain the battery system in a safety state including ensuring that the battery cells do not operate outside of their specified operating regions for voltage, current and temperature under charging, discharging and other conditions of use. The battery tests in UL 1973 are grouped into electrical, mechanical environmental tests and required per the evaluation of the stationary battery.

UL 1973 is a standard that can be used for most battery technologies and for capacitor and hybrid capacitor and battery systems. UL 1973 references several standards for cell and capacitor criteria, and also contains quite a bit of technology specific criteria that include cell test programs for secondary lithium cells. UL 1973 also has several appendices that have specific criteria for sodium beta technologies such as sodium sulfur and sodium nickel chloride and flow batteries such as vanadium redox and zinc bromine.

More Applicable UL Standards for Battery Energy Storage Systems

UL 9540 Standard for Energy Storage Systems and Equipment

UL 1642 Standard for Lithium Batteries (Cells)

UL 1973 Standard for Batteries for Use in Stationary Applications

UL 1741 Standard for Inverters, Converters, Controllers and Interconnection System Equipment

UL 1564 Industrial Battery Chargers

UL 1008 Standard for Transfer Switch Equipment

UL 3001 Outline for Investigation for Distributed Energy Generation and Storage Systems

UL 1778 Uninterruptible Power Supply Systems

ATEN BESS: A Certified and Complete Battery Energy Storage Solution

Figure 2 ATEN 250kW

ATEN is AGreatE’s line of all-in-one Commercial Battery Energy Storage Systems (BESS) for commercial and industrial applications. The ATEN product line covers a wide variety of energy storage needs and can scale from a 30 kW inverter with 64 kWh of storage to a 500 kW inverter with 1000 kWh of storage. Larger scale BES systems are also available upon request. ATEN is designed for either grid connected or totally off grid applications and offers commercial and industrial customers turn key energy storage systems that are designed for 10+ years of hassle free usage.

ATEN pairs seamlessly with a number of different energy sources. Typically Solar, Grid, and Diesel Gensets are paired together to make mini-grid applications.

About AGreatE Inc.

AGreatE is a clean energy company founded in 2017 by a group of scientists & engineers based in NY State who strive to offer zero emissions clean energy solutions making renewable energy affordable and accessible for all.

Our manufacturing facilities based in China produce high performance lithium ion phosphate battery modules, packs, racks, and all-in-one BESS that utilize AI embedded BMS and EMS systems thus improving both performance, efficiency and fire safety. AGreatE’s focus on the R&D of AI-embedded battery management systems (BMS) and energy management systems (EMS) allows current and future BESS projects to improve energy system optimization, boost cycle life expectancy, and raise the stability & safety of the deployed systems.

AGreatE’s clean energy ecosystem includes multiple product lines that integrate various distributed renewable energy generation sources (e.g. wind and solar) with its battery based energy storage systems including residential, commercial, industrial, microgrids, and utility applications. Each system includes the ability for homeowners, businesses, and utilities to manage renewable energy generation, storage, and consumption.